Saturday 18 December 2021

BEG Week 2 Session1 Dimensioning Exercises

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

Friday 17 December 2021

BEG – WEEK 2 SESSION 1 Dimensioning

BEG – WEEK 2 SESSION 1

STUDY MATERIALS

Syllabus

ü 1. Demonstrate

the dimensioning and its necessity, methods, and principles,

ü 2. Sheet no.2 Dimensioning of overall sizes, circles,

threaded holes, chamfered surfaces, angles, tapered surfaces, holes, equally

spaced on P.C.D., countersunk holes, counterbored holes, cylindrical parts,

narrow spaces and gaps, radii, curves, and arches.

Principles of Dimensioning

The following are the basic principles of dimensioning:

1. All dimensional information necessary to define a part clearly and

completely shall be shown directly on a drawing.

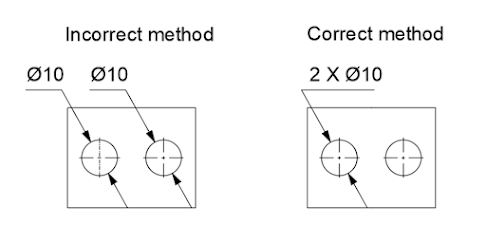

2. Each feature shall be dimensioned once only on a drawing.

3. Dimensions shall be placed on the view or section that shows clearly,

the corresponding features

4. As far as possible, on a drawing, dimensions should be

expressed in one unit only, preferably in millimeters, without showing the unit

symbol (mm). Unit on the drawing, however, may be shown in a note

5. No more dimensions than are necessary to define a part

shall be shown on the drawing. No feature of a part shall be defined by more

than one dimension in any one direction

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

Monday 13 December 2021

BEG - Week 1 Session 2 Lines and Material conventions

Lines and Material conventions

1. Demonstration of various lines and material conventions

2. Sheet no 1. Draw the conventions of lines and materials

When you are preparing drawings, you will use different types of lines to convey information. Line characteristics, such as widths, breaks in the line, and zigzags, all have definite meanings.

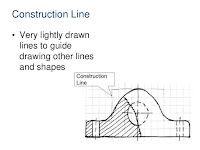

Construction Lines

Usually, the first lines that you will use on a drawing are construction lines. These are the same lines that you used to layout your drafting sheet. They will also be used to layout the rest of your drawing. Line weight for construction lines is not important since they will not appear on your finished drawing. They should be heavy enough to see, but light enough to erase easily. A 4H to 6H pencil with a sharp, conical point should be used. With the exception of light lettering guidelines, all construction lines must be erased or darkened before a drawing is reproduced

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

Saturday 11 December 2021

Basic Enginnering Graphics

What is Engineering Drawing?

In engineering drawing, engineering-related objects like buildings, walls, electrical fittings, pipes, machines, etc. are represented with specifications like size, shape, materials, etc. Several engineering drawing software with more accuracy is available. But, drawing on paper is still being used in some areas and for small machine elements.

Importance of Engineering Drawing

Instruments Used in Engineering Drawing

- Drawing sheet

- Drawing board

- Mini drafter

- T square

- Compass

- Divider

- Set squares

- Clinograph

- Protractor

- French curves

- Templates

- Pencils

- Eraser

Drawing Sheet

Drawing Board

The drawing board is generally made of softwood and it is in a rectangular shape. It is used to support drawing sheets, so, the size of the board is made according to the size of the drawing sheet. The wood portions are joined by tongue and grove-type joints to prevent cracks. At the edge of the board, the straight ebony edge is provided for the T-square usage. Different types of drawing boards and their sizes according to IS classification are listed below.| Type of Drawing Board | Length X Width X Thickness (mm) |

| D0 | 1500 X 1000 X 25 |

| D1 | 1000 X 700 X 25 |

| D2 | 700 X 500 X 15 |

| D3 | 500 X 350 X 15 |

Mini Drafter

A mini drafter is an instrument that can be used for multiple functions in the drawing. It contains two arms that are adjustable to the required angle and at the end of the lower arm, a scale set is attached. The scale set contains two scales connected perpendicular to each which cannot be separated. This instrument is fixed to the drawing board at one edge with the help of a screw provided for the drafter. The mini drafter is used for drawing horizontal lines, vertical lines, inclined lines, angles, parallel lines, perpendicular lines, etc.T-Square

T square is used to draw horizontal and vertical lines on the drawing sheet. It is made of wood or plastic and in a T shape. The vertical part of T is called a blade and the horizontal part of T is called a head. The edge of the head is uniform level and attached to the edge of the board. The working edge is used to draw lines anywhere on the sheet by moving the instrument from top to bottom.

Compass

Compass is used to draw an arc or circle with known dimensions on engineering drawing. It is generally made of steel and consists of two legs. One leg contains a needle at the bottom and another leg contains a ring in which a pencil is placed. The needle tip is placed at the respected point and the pencil tip is adjusted to the height at least 1mm just above the tip of the needle. The gap is nothing but the paper thickness.

Divider

The divider looks like a compass, but the difference is the two legs of the divider are provided with needles. This is used to divide a line or curve into equal parts. It is also used to check the measurements.

Set Squares

Set squares are used to draw lines with an angle between them. In most of the structures, 30, 45, 60, and 90-degree lines are most common. So, set squares make the work easier for this type of drawing. Generally, set squares are of two types. One is a 45 degrees set square and another one is called a 30 – 60 degree set square. Both are required in the drawing. 45 set square has a side of 25 cm while 30-60 set square has 25 cm length on one side.

Clinograph

Clinograph is an instrument used to draw parallel lines to the inclined lines. It contains one adjustable wing or strip which can be adjusted to the required angle. So, it can be termed an adjustable set square.

Protractor

A protractor is used to draw and measure the angles of lines in the drawing. It is transparent and made of plastic. It is in the shape of a semi-circle, and the edge of the semi-circle part consists of reading with one-degree accuracy. The bottom line joins the 0o to the 180o. The center of this bottom line is marked as “O” or “C” from which the angles are measured.

French Curves

French curves are made of plastic and they are in irregular shapes. Sometimes the drawing requires irregular curves or shapes or arcs which cannot be drawn using a compass. In that case, French curves are suitable. Generally, French curves are more suitable for small curves, and for long curves, splines are used.

Drawing Templates

Templates are nothing but plastic or wooden boards that contains spaces of several shapes or letters. Non-dimensional shapes or variety of font letters are drawn by using templates which makes drawing easier and perfect.

Pencils

A pencil is used to draw on the paper. Any type of pencil is not suitable for drawing. There are some limitations, the drawing appearance should be very neat and understandable. Every line of the drawing should indicate its importance. It depends upon the hardness of the pencil. Based on the hardness quality pencils are classified into 18 grades and they are| Grade of Pencil | Hardness of Pencil |

| 9H | Hardest |

| 6H, 5H, 4H | Extremely Hard |

| 3H | Very hard |

| 2H | Hard |

| H | Moderately hard |

| F | Firm |

| HB | Medium-hard |

| B | Moderately soft and black |

| 2B | Soft and black |

| 3B | Very soft and black |

| 4B, 5B, 6B | Very soft and very black |

| 7B | Softest |

| Grade of Pencil | Used to Draw |

| 3H | Construction lines |

| 2H | Dimension lines, centerlines, sectional lines, hidden lines |

| H | Object lines, lettering |

| HB | Dimensioning, boundary lines |

Eraser

Eraser is used to remove the lines or spots drawn by mistake or with wrong measurements. The eraser used should be of good quality and soft. It should not damage the paper while erasing.

Paper Holders

When the drawing sheet is placed on the board it may not be in a fixed position. To fix the drawing sheet to the board paper holders are used. Generally used paper holders are thumb pins, spring clips, stick tapes, etc. Care should be taken while removing the clips or tapes otherwise the sheet may tore.

|

Setting up the mini drafter and drawing sheet. |

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

https://dseu.ac.in/faculties/s-deivanai/

Ph. D. (pursuing) – Friction Stir Welding, Indira Gandhi Delhi Technical University for Women, New Delhi;

M. Tech. – Production Engineering, Delhi Technological University, New Delhi;

B.E – Mechanical Engineering, Institute of Road and Transport Technology, Erode;

Courses teaching :

Manufacturing Technology;

Material Science;

Engineering Graphics;

Machine Drawing;

Metrology and Instrumentation;

CNC machines;

Basics of Automobile Engineering;

சுயமதிப்பீடு

தான் நல்லவன் என எப்படி தன்னைத்தானே புகழ்ந்து கொள்கிறார்கள்? தான் எழுதிய தேர்வுத்தாளை தானே மதிப்பிடுவது எப்படி சரியான மதிப்பீடாகும்? நீ நல்லவ...

-

Lines and Material conventions 1. Demonstration of various lines and material conventions 2. Sheet no 1. Draw the conventions of lines and...

-

What is Engineering Drawing? In engineering drawing, engineering-related objects like buildings, walls, electrical fittings, pipes, machin...

-

Orthographic Projection exercises Draw front view, top view ,side view of the following exercises Problem 1 Problem 2 ...

-

Technical Lettering Syllabus: 1. Introduction to lettering and its necessity. Demonstrate the construction details of Engli...